Automotive masking tapes for the automotive paint and refinish, body shop and collision repair industries. SLAA is committed to leading the automotive market by providing high-performance masking and surface protection solutions that improve productivity, product integrity, image and cost containment.

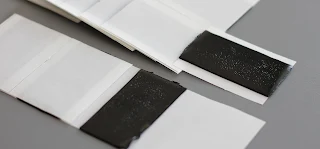

Automotive masking tape provides sharp, clean paint edges, high conformability, and holding power, with no adhesive residues when removed. It typically consists of several materials that contribute to its effectiveness and performance. Here are the main materials included in automotive masking tape:

No.1710

Cost-effective Off-white masking tape.

Crepe paper coating Natural rubber adhesive for masking in the body shop.

Clean removal up to a drying cycle of 100°C (30 min).

No.163

High-performance colorful masking tape.

Colored Crepe paper coating Natural rubber adhesive for Automotive spray painting.

Good strength to prevent breaking and adapt to irregular surfaces.

No.1630

UV resistant Lemon yellow masking tape.

Crepe paper coating Natural rubber adhesive for Automotive spray painting.

Clean removal up to 3 days after outdoor masking or a drying cycle of 90°C (30 min).

No.1636

Waterproof & UV resistant masking tape.

White, Orange, Lemon yellow.

Crepe paper coating Natural rubber adhesive for wet sanding and spray painting.

Clean removal up to 3 days after outdoor masking or a drying cycle of 100°C (30 min).

No.1528

High temperature automotive masking tape.

Beige, Medium Green

Natural rubber adhesive for the medium to high end automotive repair market.

Compatible with both water and solvent based paints.

Clean removal after electronic application masking at 120°C (30 min).

No.1529

High temperature critical automotive painting masking tape.

Beige, Green

Specially designed rubber-based adhesive formula for a temperature resistance of up to 130°C for 30 minutes.

It’s strong solvent-resistance ensures that the tape will not break down or dissolve when exposed to solvents commonly used in the automotive painting process.

The tape conforms well to irregular surfaces, ensuring a tight seal and preventing any bleed-through or wrinkling during the application process.

No.9244

Precision line body shop masking tape.

Yellow Washi paper coating water based Acrylic adhesive.

Clean removal up to a drying cycle of 130°C (30 min).

Conforms well to small and curve body parts, narrow grooves.

UV rays resistant and clean removal up to 3 days.