Automotive masking tape No.3758 for use both water based and solvent based paints. This painters tape ideal for car paint masking, heat resistant and UV resistant.

Features

- Excellent adhesion to tape on tape and with masking paper and protective film.

- Clean, flat edges for clean and precise paint lines.

- 3 days UV & Water Resistant.

- Excellent solvent and water resistance.

- High temperature (110°C) resistance.

- Without bleed through.

- Excellent edge tear.

Painter's Tape Description

No.3758 automotive masking tape is made with apple green washi paper with Acrylic adhesive, specific for automotive car painting application during drying cycles at high temperatures up to 110°C. This painters tape guarantees high adhesion and doesn’t leave adhesive traces when removed.

Technical Data Sheet

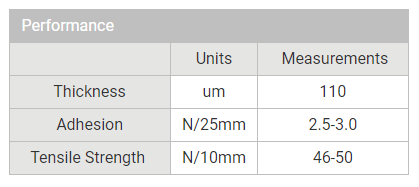

Adhesive Type: Water-based acrylic adhesive.

Backing / Carrier: Apple green washi paper.

Total Thickness: 110 µm.

Tensile strength: 46-50 N/cm.

Adhesion to steel plate: 2.5-3.0N/cm.

Service temperature: up to 110°Painter's Tape Applications

Automotive masking tape is commonly used to protect specific areas of a vehicle’s surface from accidental damage or overspray during painting, refinishing, or clear coat applications. This painters tape can be applied to areas such as windows, trims, door handles, mirrors, and headlights to shield them from paint or chemical exposure.

It performing extremely well when used tape on tape and with masking paper and protective film. When this tape masking on car body, it maybe need large area to masking. The Pre-taped masking film is a drop sheet that pre-folded film rolls. It makes masking better, faster and easier.